What is motor production line?

The automatic motor production line, also known as the motor assembly line, includes the assembly of brushless motor and brushed motor. Specific to the parts, it also includes the assembly of the stator, rotor and air pumps. Domestic motor manufacturing equipment combines the technical characteristics of Japan, Europe and the United States, after innovative research and development, the motor production line is stable, efficient, intelligent and safe. Motor manufacturing equipment makes full use of the stable production capacity of mechanical equipment and high equipment utilization, allowing brushless motors and brushed motors to be quickly mass-produced. Stator and rotor windings can also ensure efficiency and quality, and save copper wires.

5 advantages for motor manufacturers to choose motor production line:

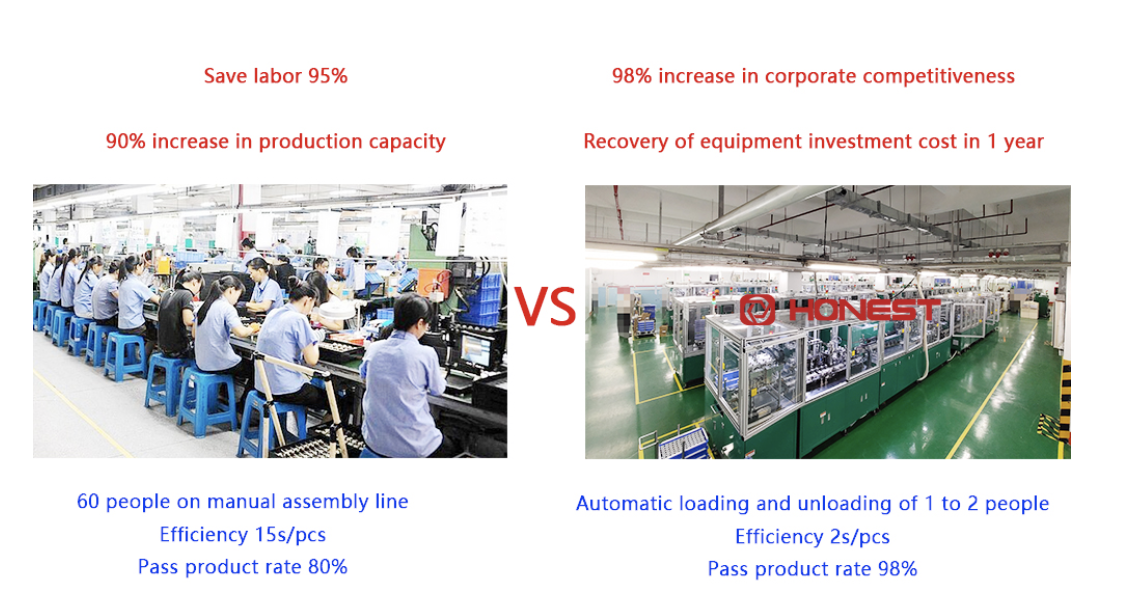

1.Reduce labor and management costs.

For example, a manual production line with 60 workers is replaced by a fully automatic motor production line, and it only requires 2 to 3 people to replace manual assembly with automated equipment. Save labor and management costs to the greatest extent. The fully automatic motor assembly line is controlled by computer system, and only requires professionals to set up before production, and then it can be produced and assembled as required.

2.Improve production efficiency and ensure product quality, shorten the production cycle and reduce human error.

Fully automatic motor production equipment is a high-precision equipment with very strict requirements on products, which can effectively reduce the generation of defective products. In addition, motor automation equipment is usually compatible with dozens of similar products and can quickly achieve product model conversion. Manual assembly also requires time to learn the assembly process in the early stage. Compared with manual assembly, the output of the fully automatic motor production line has increased several times, and the production efficiency of the enterprise has been effectively improved.

3.Improve the comprehensive competitiveness of enterprises, such as increasing production capacity and obtaining more high-quality large orders, thus triggering the butterfly effect.

In some large and medium-sized motor manufacturing companies, we can see that factories have invested in fully automatic motor production equipment, which also shows that industrial automation and intelligent production are the industry development trend.

4.Industrial upgrading, optimizing industrial structure.

Streamline the company’s personnel and optimize the department structure, so that the company can get more profits. Generally speaking, if the output demand is high and the price of the motor sold is high, the investment in the motor assembly line can be paid back for one or one and a half years. If the output requirements and the price of the product are low, then recover investment when deciding to put into the automated production line will be spend more time. Not necessarily suitable for investment, so need comprehensive assessment.

5.Industrial automation and information technology, intelligent production.

Improve material planning and reduce waste. Optimize the production process, the system automatically feedbacks and traces the source of the problem. Reduce downtime and get greater revenue and profits.