These days, it seems like every company is trying to save every penny they can get their hands on. And with the price of living skyrocketing, people are feeling more and more pressure to cut costs. But where do you start? There are so many different aspects of your company that can be cut! These five aluminum die casting manufacturers in Taiwan offer some of the cheapest prices on the market today. With these new suppliers, you’ll never have to worry about how costly it is to run your business.

The top 5 cheapest aluminum die castings manufacturers in Taiwan

These five Taiwanese aluminum die casting manufacturers offer some of the lowest prices on the market today while still providing high-quality products and services.

TEAMSWORLD Customized Die Casting and Plastics Injection Molding Solutions Taiwan

Teamsworld is a B-Corporation with innovations for sustainable consumption. In order to meet future demands without causing environmental harm, the company aspires to use resources and products in a sustainable and responsible manner. They are an aluminum die castings manufacturer in Taiwan that connects foreign buyers with Taiwanese suppliers through integrated consulting solutions for customized metal and plastic parts in the industrial industry. As a result, they will be able to create flexible and resilient supply chains in the industrial sector.

Teamsworld die casting taiwan has been providing manufacturing, product development, supply chain management, agile management, and resilient production in the lighting, automotive, electronics, subcontracting, metal parts, plastics parts, sustainable management, die casting, and plastic injection industries since 1977. As an aluminum die castings manufacturer taiwan, they offer customized services such as surface treatments, heat treatments, and mechanical treatments on castings, as well as design, mold, product, finish treatment, and assembly. They also customize assembly parts in accordance with EU / US standards to match customer’s marketing goals.

Peng Ming Enterprise Company

Peng Ming Enterprise CompanyT, also known as Taiwan Die Casting Company, is located in a well-equipped industrial estate, a 10,000-square-foot industrial park in Taoyuan City’s Guishan District. The company was established in 1980. They specialize in precision die casting of zinc alloy, aluminum alloy, and mold design, and they work with people and businesses from all over the world. Many other industries would collapse if it weren’t for companies like Peng Ming developing molded alloys for firearms, automobile , and technology industries. Peng Ming Enterprise Company plays an important role in stabilizing the economic growth of other countries around the world. They are also certified by the International Organization for Standardization, which constantly audits companies to ensure they are meeting their high customer satisfaction standards. Not only that, but they are constantly reviewed to ensure that their products are of high quality and are sold to customers at reasonable prices. This enables the company to establish long-term business relationships with its customers.

Golden Pond Metal Die Casting Co., Ltd

Golden Pond Aluminum Die Casting Manufacturer, one of Taiwan’s oldest aluminum alloy die casting manufacturers, was founded in 1947. For OEM/ODM, the company provides superior aluminum die casting technology, services, and custom design. They conduct casting design reviews with customers prior to mold making to ensure appropriate mold development for each design and enhance the value of aluminum alloy die castings and avoid possible problems in the future. Their diverse product offerings can be used in a variety of industrial applications. These long-lasting and high-quality molds are used in industries all over the world, from FMCG to electronic manufacturing. They use modern, well-maintained, and exceptional machines to produce high-quality products. They specialize in producing zinc and aluminum alloys that can be cast into a wide range of shapes, sizes, and industrial applications with no mechanical constraints.

Ted-Yue Precision Die Casting Co., Ltd

Ted-Yue Precision Die Casting Co., Ltd has established itself as one of Taiwan’s leading suppliers. Founded in 1983, the manufacturer is based in New Taipei City, Northern Taiwan, and is one of the leading sellers of Aluminum Products, Zinc Products, Led/ Lighting Components, Electronic Components, Auto Parts, Industrial Hardware Components, and Electronic Components. In addition, they offer design and OEM services. They provide complete post-processing automatic CNC technology, various types of perfect surface treatment such as electroplating, paint baking, polishing, grinding, vibration, and consistent operation of assembly and delivery, in order to achieve the customer service goal of highest quality and fast delivery. Since 2007, TEDYUE has been ISO 9001/2000 certified, and they have also established one new business department in order to enter the international market.

HF-TI Precision Molding Manufacture Co., Ltd

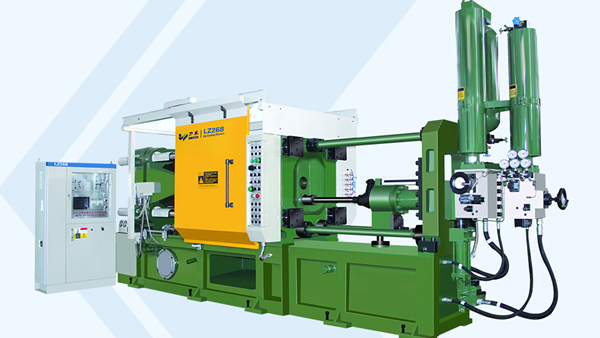

HF-TI Precision Molding Manufacture Co., Ltd has over ten years of experience in mold development technology and production . They have a team of molding technical experts at HF-TI, and they specialize in precision die casting and thinner walls. In addition, the company has used foreign high-precision measuring instruments and machinery. Their products include zinc, aluminum alloy die castings, and plastic optics, electronics, optical communications, computers, mobile phones, antenna connectors, hardware, etc; hot zinc alloy die casting machines range from 15 tons to 100 tons, cold aluminum alloy die casting machines range from 80 tons to 150 tons, and foreign – made high-precision machines. They can also offer self-model proofing, mold design, mold opening, small test, mass production, post-processing, surface treatment, and other solutions to save customers time and increase efficiency.

How to find suppliers of aluminum die castings

If you want a high-quality product, you must find a reputable, trustworthy aluminum die-cast manufacturer. Around the world, there are numerous aluminum die castings manufacturers. Online marketplaces such as Alibaba, are the right place to look for manufacturers of high-quality aluminum die castings. To review and locate suppliers, you can also search supplier online directories or you need to visit the company’s website and take notes on company profiles, website links, location information, phone numbers, product videos, customer reviews, product-specific articles, and other manufacturing data. But, It is preferable to work with a foreign trade agent or sourcing agent who has long-term relationships with prominent overseas manufacturers.

What alloy is the best material for your company?

Choosing the best metal alloy for your company necessitates a thorough understanding of the industry as well as extensive research.

When it comes to alloy materials, there are four things to keep in mind:

-

Learn about the various metal materials that are available.

Metal alloys have distinct properties that affect the function of a product, the material used, or the quality of the equipment produced.

-

Understand the properties of each metal material.

Metal materials’ strength and properties vary greatly depending on the type of metal. As a result, in many cases, the application determines the type of material to be used.

-

Understand how the processing method affects the properties of each metal material.

Consider the conditions the alloy will be exposed to as well as the specific functions the alloy will perform when choosing the best metal alloy.

-

Choose the best metal material for your needs.

In other words, for manufacturing, it is important to “select materials” after understanding the characteristics of materials and processing technology.

Why are aluminum die castings the new industry standard?

Aluminum die casting makes it possible for a higher production rate than many other metal alloys. This technique is also less expensive. Aluminum has the advantages of being light, heat-transmitting, and simple to process. On the other hand, because it is soft, it is easily scratched and has a lower strength than iron. As a result, by combining it with metals like copper and magnesium, as well as silicon, it has become possible to create materials that are stronger, lighter, and better at transferring heat.

Conclusion

Finally, when looking for an industrial metal supplier, you want to work with a company that is knowledgeable about the product. If necessary, ask for a reference to confirm the supplier’s expertise and reputation. Many suppliers have seemed to ignore or forget their customers, which may surprise you. Good communication, like anything else, is the key to a successful relationship.